Solutions

TrypsiNNex® applications

Addressing contamination challenges in bioprocessing

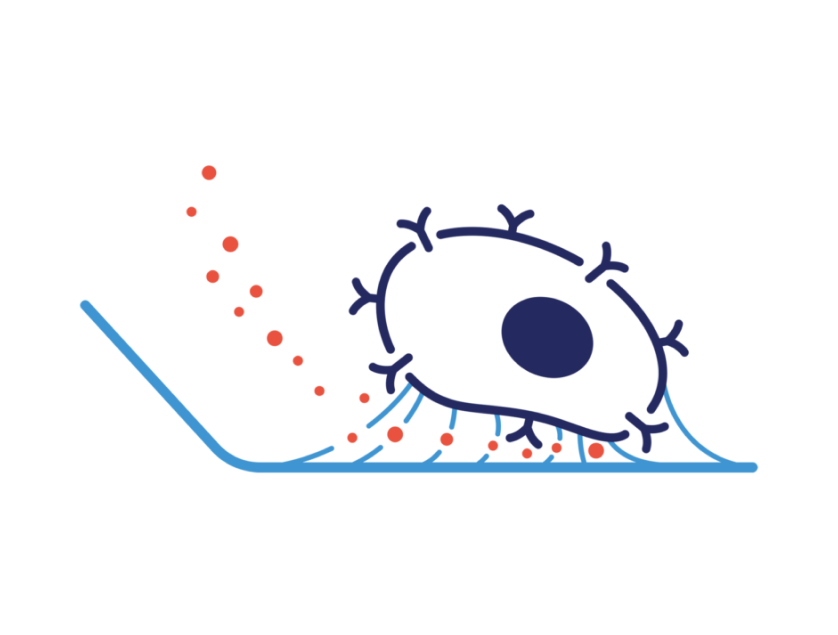

The production of biologic drugs using mammalian cells ensures proper protein folding, and reliable post-translational modifications. However, the complexity of mammalian cell culture requires significant optimization to achieve consistency and in addition is vulnerable to contamination with adventitious agents.

Quality and safety measures for biopharmaceutical production encompass the careful selection of raw materials with minimal risk of harboring adventitious viruses. Despite rigorous testing, the infection of production cell cultures remains a significant concern with serious consequences.

Adventitious virus contamination during cell culture manufacture of a biologic is incredibly disruptive. Investigating a viral contamination event costs both time and resources. According to Barone et al. 2020, the expense of such an investigation, as reported to the CAACB, was in the $1–10 million range, but in the worst cases the cost of investigating a contamination, implementing corrective actions, decontaminating the facility, and other ancillary costs could be in the hundreds of millions of dollars.

Such contamination can result in loss in revenue due to a competitive disadvantage, manufacturing interruptions, discarded batches, lawsuits, decrease in company reputation, and significant delays in product development. Far worse, these events can affect patients.

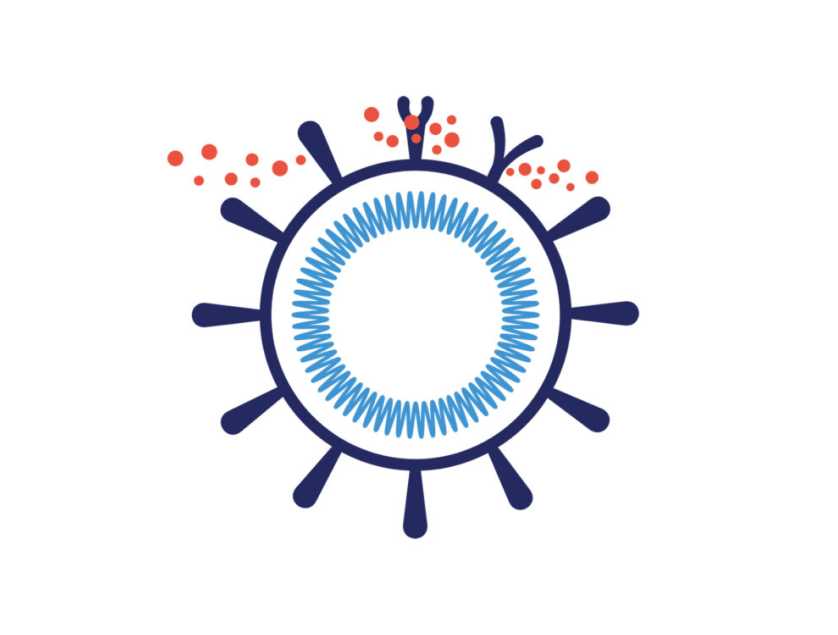

Raw materials of animal origin have an elevated risk of viral contamination. Data presented by Barone et al. 2020 show that materials testing alone fails to guarantee the absence of viruses in a product. Of 11 production contamination events examined, raw materials were identified as the probable source testing detected viral contamination of raw materials in only 3 cases.

According to Moody et. al (2011) viral contamination may be “silent,” with no impact on cell viability and product titers. Furthermore, contamination may not be detected using in vitro virus assays, and assays based on PCR (polymerase chain reaction) are required for reliable detection.

Although testing is a key component of viral safety in biotechnology products, present data indicate that testing alone is not enough to ensure that a given product is free of a viral contaminant, and that a holistic, multifaceted risk-management approach must be taken. And since even animal-free raw materials can be a source of contamination, biopharmaceutical manufacturers must also invest in sourcing from reliable suppliers offering reliable quality controls and raw material traceability.

Explore the many applications and learn how it can help support your formulations.

Why use TrypsiNNex®

The proteolytic activity of trypsin is an indispensable tool in both biological research and biopharmaceutical manufacturing. Trypsin is used in protein identification, quantification, and modification; in cell culture; and in tissue engineering. Demand for trypsin is significant and has predominantly relied on animal-derived trypsin. But more recently, safety regulations in biopharmaceutical manufacturing have made microbially expressed recombinant trypsin more viable than enzymes sourced from porcine or bovine pancreatic tissue.

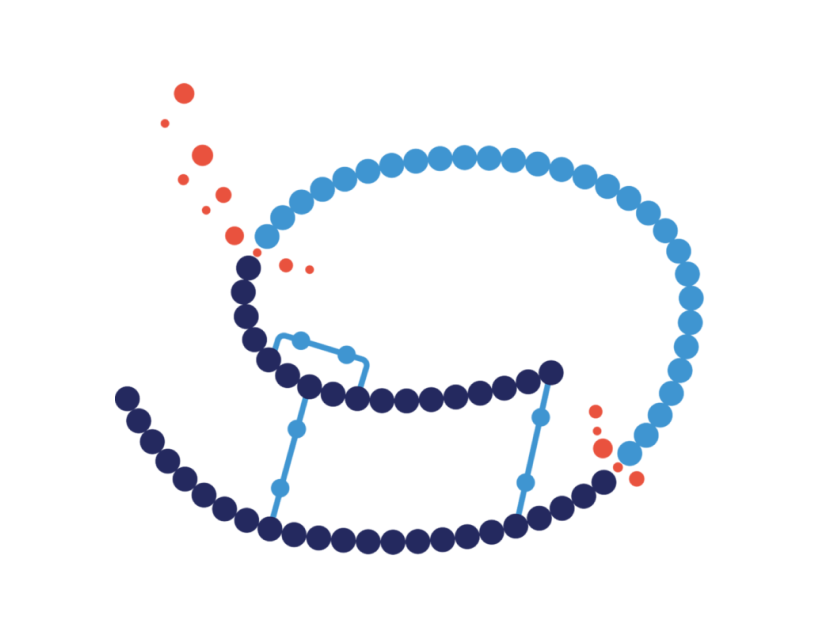

TrypsiNNex® is manufactured under stringent quality standards and aligns with industry standards for non-animal origin raw materials and reagents. It essentially eliminates the potential for contamination by adventitious agents, proteases like chymotrypsin, and other impurities.

TrypsiNNex® specifically addresses the need for a consistent, high-purity and high-quality enzyme in biopharmaceutical manufacturing. This recombinant enzyme is expressed in Escherichia coli as an inactive protein and first becomes activated during the subsequent purification process. The short time interval between activation and stabilization curtails premature degradation and thus safeguards a substantial proportion of intact trypsin. As a result, overall purity of TrypsiNNex® exceeds 90%.

The performance of TrypsiNNex® has been extensively tested by independent research institutes. Read more in our application notes below.

Quality and safety measures for biopharmaceutical production encompass the careful selection of raw materials with minimal risk of harboring adventitious viruses. Despite rigorous testing, the infection of production cell cultures remains a significant concern with serious consequences.

Adventitious virus contamination during cell culture manufacture of a biologic is incredibly disruptive. Investigating a viral contamination event costs both time and resources. According to Barone et al. 2020, the expense of such an investigation, as reported to the CAACB, was in the $1–10 million range, but in the worst cases the cost of investigating a contamination, implementing corrective actions, decontaminating the facility, and other ancillary costs could be in the hundreds of millions of dollars.

Such contamination can result in loss in revenue due to a competitive disadvantage, manufacturing interruptions, discarded batches, lawsuits, decrease in company reputation, and significant delays in product development. Far worse, these events can affect patients.

Raw materials of animal origin have an elevated risk of viral contamination. Data presented by Barone et al. 2020 show that materials testing alone fails to guarantee the absence of viruses in a product. Of 11 production contamination events examined, raw materials were identified as the probable source testing detected viral contamination of raw materials in only 3 cases.

According to Moody et. al (2011) viral contamination may be “silent,” with no impact on cell viability and product titers. Furthermore, contamination may not be detected using in vitro virus assays, and assays based on PCR (polymerase chain reaction) are required for reliable detection.

Although testing is a key component of viral safety in biotechnology products, present data indicate that testing alone is not enough to ensure that a given product is free of a viral contaminant, and that a holistic, multifaceted risk-management approach must be taken. And since even animal-free raw materials can be a source of contamination, biopharmaceutical manufacturers must also invest in sourcing from reliable suppliers offering reliable quality controls and raw material traceability.

Explore the many applications and learn how it can help support your formulations.

References:

Barone et. al | Nature Biotechnology | VOL 38 | May 2020 | 563–572 |

Moody et al. | Conference proceedings of the PDA/FDA Adventitious viruses in biologics | Published 2011

You can also request a product sample to experience its capabilities in your own environment

Explore more about TrypsiNNex®

TrypsiNNex®

Reduce resources needed for validation, improve process consistency and reduce costs due to contamination risk with our animal-free, recombinant TrypsiNNex®.