Benzalkonium Chloride

Excipients

Excipients play a central role in the drug development process, in the formulation of stable dosage forms and in their administration.

What are excipients?

Active substances are rarely administered alone. The active substance often represents a very small portion of the finished drug formulation, where the remaining is composed of excipients.

Excipients play a central role in the drug development process, in the formulation of stable dosage forms and in their administration. A bad choice of excipient can even lead to severe intoxications or even fatal outcome, as unfortunately experienced several times by patients in different parts of the world.

Definition of excipients

Excipients are often defined as an ingredient other than the active substance, contained in a dosage form.

The International Pharmaceutical Excipients Council (IPEC) points out the different possible functions fulfilled by excipients: “Excipients are all substances contained in a dosage form other than the active substance or finished dosage form, which have been appropriately evaluated for safety and are included in a drug delivery system to either aid the processing of the drug delivery system during its manufacture, protect, support, enhance stability, bioavailability, or patient acceptability, assist in product identification, or enhance any other attributes of the overall safety and effectiveness of the drug delivery system during storage or use.”

Multifunctionality of excipients

The difference between an excipient and an active substance is not always clear. Some excipients are sometimes also used as active substances, as is the case for Quats. Quats can be multi-functional; they are used as antimicrobial preservatives, to enhance the stability of a preparation, and being positively charged surfactants with both a hydrophilic and a hydrophobic group, they can also enhance permeation and promote absorption of a preparation – thereby impacting on the bioavailability of a drug.

The functionality of an excipient can be determined by its physicochemical properties and its molecular structure. It may also depend on complex interactions between the constituents of the formulation and on stresses related to the manufacturing process. Thus, the functionality of a specific Quat can only be evaluated in the context of a particular formulation and manufacturing process, and by a number of analytical methods.

Quats as safe and effective pharmaceutical excipients

Multidose pharmaceutical products are prone to contamination, both from environmental and corporeal flora. Microbial contamination can present a threat to the safety, the purity or the efficacy of the drug products, hence the importance of utilizing an effective preservative. It is necessary to preserve against contamination by utilizing only the purest and safest ingredients. This can be ensured by choosing GMP manufactured excipients that comply with relevant ICH and IPEC guidelines and pharmacopoeia.

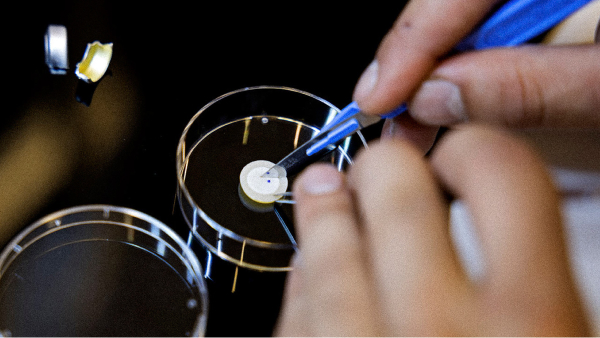

For example, in both human and veterinary ophthalmics, one of the most common and effective preservatives is Benzalkonium Chloride (BKC / BAK). Benzalkonium Chloride has been in use as an antimicrobial preservative in eye drops since the early 1940s, and remains the preservative of choice in multidose ophthalmic and nasal delivery formulations. Its concentration would typically be 0.001%-0.005% in ophthalmic formulations and slightly higher, 0.01%-0.05% in nasal sprays.

Our Benzalkonium Chloride comes in an unequalled, full cGMP grade. Our multi-compendial range of Quats complies to the highest regulatory guidelines, including ICH Q7, the European Pharmacopoeia (Ph. Eur.), the United States Pharmacopoeia (USP), the Japanese Pharmacopoeia (JP).

Our stringent Quality Management System ensures the right quality products, with a high degree of consistency. We receive excellent ratings in audits from our customers and authorities, including the FDA and EMA, and continue to improve from every audit.

Manage risks

By sourcing an excipient at API level, you are given access to a full documentation package including change control, high batch-to-batch consistency provided by validated processes, and full supply chain traceability.

For many pharmaceutical and biopharmaceutical companies, the coronavirus pandemic has put supply chains to the test, while regulatory requirements are increasingly tightening. Novo Nordisk Pharmatech helps customers reduce their risk, with a high level of consistency in both the quality and supply of our Quats. You can be sure you get the same high quality product, time after time, reliably delivered through local distribution networks. Our comprehensive documentation package and tailored support, which continues through the whole product life cycle, gives you total peace of mind.

Explore more

Valuechain

Novo Nordisk Pharmatech improves biopharmaceutical manufacturing by developing and supplying innovative products used in the manufacturing of biopharmaceuticals.