Company

Valuechain

High quality, consistent and reliable cGMP manufactured Quats that enables better processes, minimize potential risks, and give you peace of mind.

Novo Nordisk Pharmatech improves biopharmaceutical manufacturing by developing and supplying innovative products used in this process. Biopharmaceuticals are medicines based on biological molecules, such as insulin, growth hormone, and blood coagulation factors.

In this way, Novo Nordisk Pharmatech improves biopharmaceutical manufacturing and makes biopharmaceuticals cheaper to produce, thereby enabling better patient access to medicine.

A wide range of capabilities are available at Novo Nordisk Pharmatech within the various departments:

- R&D

- Manufacturing

- Quality

- Sales and Marketing

- People & Organisation

All capabilities present in the company are critical for Novo Nordisk Pharmatech to run the business and innovate.

The following “Core Capabilities” are those that stand out as unique to Novo Nordisk Pharmatech, and are fundamental to the future growth of the company:

Solid phase synthesis of customised purification resins

Highly specialised expertise within coupling chemistry applied for the customisation of purification resins with optimised performance and efficiency.

Downstream purification of specialty enzymes

Dedicated knowledge within downstream purification of superior enzymes with high purity and consistent activity.

Organic synthesis of small molecules

Long history and know-how in organic synthesis of high-quality quaternary ammonium compounds customised for pharmaceutical applications.

High quality and proven reliability

cGMP manufacturing in compliance with global regulatory requirements.

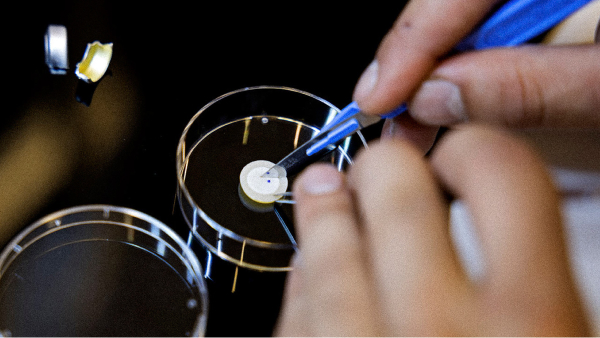

Extensive analytical quality control supported by a state-of-the-art microanalysis centre.

Well-characterised raw materials and packaging solutions

At Novo Nordisk Pharmatech, we are committed to bringing forward pharmaceutical materials that enable better medicines for our customers in a sustainable way.

We are proud that our innovative research and products take part in aiding millions of people around the world to live better lives and we are committed to making a difference with products benefitting people suffering from serious chronic diseases.

We provide products to aid pharmaceutical manufacturing within four technology platforms:

- We provide high-quality insulin to enhance expression.

- We provide superior enzymes for modification.

- We provide customised resins for purification.

- We provide chemically synthesized molecules for formulation.

We aim to grow our leading position within media components and expand our portfolio of process enzymes. Further, we want to secure an increased supply of innovative, efficient resins and, finally, strengthen the position of Benzalkonium Chloride (BKC) in the pharmaceutical market.

Novo Nordisk Pharmatech has a long history of continuously reducing the cost of insulin production for Novo Nordisk by providing robust silica gels and developing processes to increase their lifetime.

Our R&D pipeline comprises several new products under development. Every new product goes through the four phases:

1.

Idea phase, where the potential value of the product is analysed

2.

The R&D phase, where the product is developed in the lab in close collaboration with customers

3.

The tech transfer phase, where the technology is transferred to production and the production facility is built

4.

The launch phase, where the product is introduced to the market

We ensure high quality in our products by meeting the expectations and needs of our stakeholders. We strive for simplicity and never compromise on quality.

The development of new products is based on the requirement from the customers and the final use of the product. Quality by design is used during development to ensure that quality is built into the product, with a high focus on product and process understanding, as well as on process control as opposed to relying on testing of the final product.

From development through tech transfer to production, our Quality Management System (QMS) ensures that knowledge is handed over, thereby ensuring that employees understand both why and how to ensure quality.

It is part of our strategy to safeguard product quality and compliance, thereby safeguarding the patient.

Our QMS is based on ISO 9001 and covers processes from development to post-delivery activities. We strive for simplicity and we develop and maintain a process-oriented QMS based on our stakeholders’ expectations, as well as legislation and requirements from authorities, eg “EU GMP vol. 4 part II”, “ICH Q7” and “The Joint Good Manufacturing Practices Guide for Pharmaceuticals Excipients”.

The drug substance production is inspected by the Danish Medicines Agency on a regular basis and we are also inspected by the FDA. Audits from our customers are part of our quality agreements with them. Historically, the results of these inspections and audits have shown a very high level of compliance.

Explore more

Collaboration

A successful collaboration starts with understanding. Learn how we can help bring your next idea or innovation to life.